| Material | Type | galvanized steel sheet |

| Thickness(mm) | 2.0-4.2 | |

| Yield strength | Q235 or 34Ksi | |

| Roller material | GCr15 bearing steel with quench treatment | |

| Forming speed(m/min) | About 1500-2000mm/min or 4-5m/min. For option | |

| Step distance | Adjustable according to requirement (>=250mm) | |

| Speed adjusting mode | AC Frequency | |

| Roller drive | Decelerating motor + Chain drive | |

| Type of cutting | after roll-formed and length-set cutting | |

| Cutter material | Cr12 mold steel quench treatment | |

| Length measurement | Encoder | |

| Control mode | Mitsubishi PLC | |

| Operating mode | Button + Mitsubishi Touch screen | |

| Main motor power(kw) | 22KW *2 (Depend on final design) | |

| Hydraulic station power | 11K W (Depend on final design) | |

| Total power(kw) | 56KW (Depend on final design) | |

| Uncoiler’s loading capacity | Max. Capacity: 5000kgs (can be increased to be 10T) |

|

| Machine`s size | About 15.5*1.8*1.9m (Depend on final design) | |

| Machine weight | About 32000kgs | |

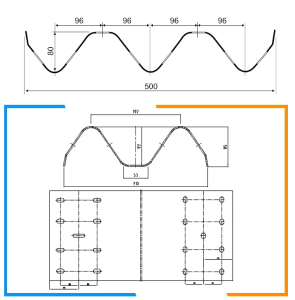

Drawing of the highway guardrail

working flow of highway guardrail roll forming machine

Hydralic decoiler-feeding table-Leaving device-punching system-roll forming rollers-cutting system-output stacher

|

|

|

1. About Us

We are a manufacturing enterprise based in Cangzhou, Hebei Province, China, established in 2013. Our primary export markets include South America (30%), Oceania (20%), Africa (20%), North America (10%), the Middle East (10%), and Southeast Asia (10%). Our team comprises 11-50 professionals dedicated to delivering excellence.

2. Quality Assurance

Prototype testing prior to bulk production

Rigorous final quality checks before dispatch

3.Our Product Range

We specialize in manufacturing:

– Roof & Wall Roll Forming Systems

– Floor Deck Fabrication Machinery

– Light Steel Keel Production Equipment

– CZ Purlin Roll Forming Units

– Precision Leveling & Slitting Machines

4.Competitive Advantages

① Full-spectrum manufacturer of roofing machinery and related equipment.

② Decade-long industry expertise with cutting-edge technological solutions.

③ Dedicated R&D division and 24/7 customer support team.

5. Service Capabilities

– Delivery Terms: FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

– Transaction Currencies: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF

– Payment Options: T/T, L/C, MoneyGram, Credit Card, PayPal, Western Union, Cash, Escrow

– Languages: English, Chinese, Spanish, Japanese, German, French, Russian