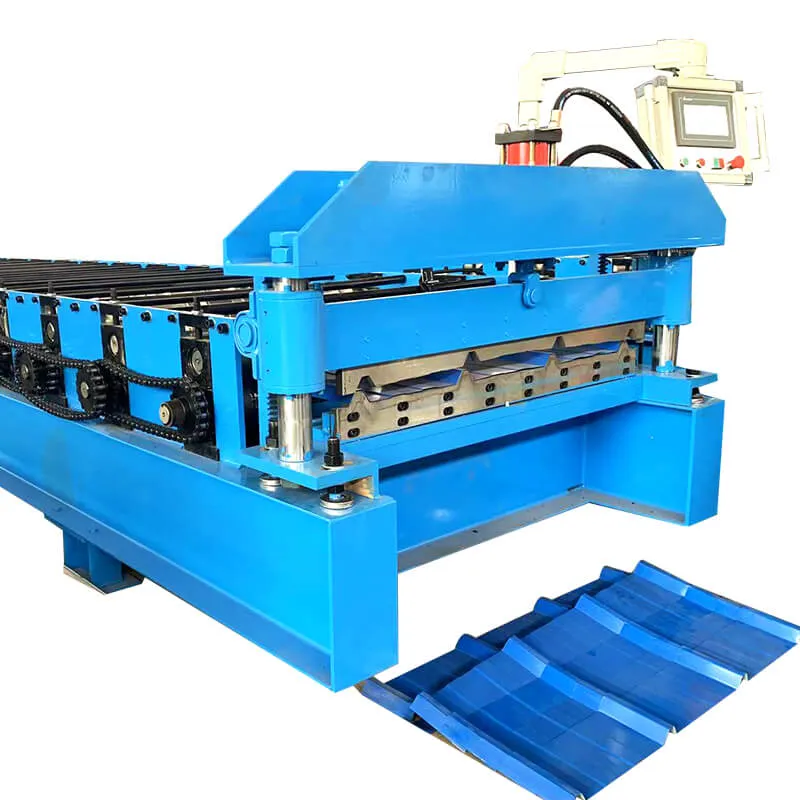

Línea de producción de componentes para perfiladora de chapa trapezoidal

Componentes principales de la máquina perfiladora de chapa trapezoidal |

|||||||||

| artículo | Descripción del artículo | Unidad | Cantidad | ||||||

| 1 | Desenrollador de 5 toneladas | configure | 1 | ||||||

| 1 | Dispositivo de alimentación y guiado | configure | 1 | ||||||

| 3 | Máquina principal de perfilado | configure | 1 | ||||||

| 4 | Estación hidráulica | configure | 1 | ||||||

| 5 | Sistema de control | configure | 1 | ||||||

| 6 | Dispositivo de corte | configure | 1 | ||||||

Especificaciones principales de la máquina perfiladora de chapa trapezoidal |

|||||||||

| 1 | materiales | PPGL | |||||||

| 2 | espesor de los materiales | 0,3-0,8 mm | |||||||

| 3 | Velocidad | 20-25 m/min | |||||||

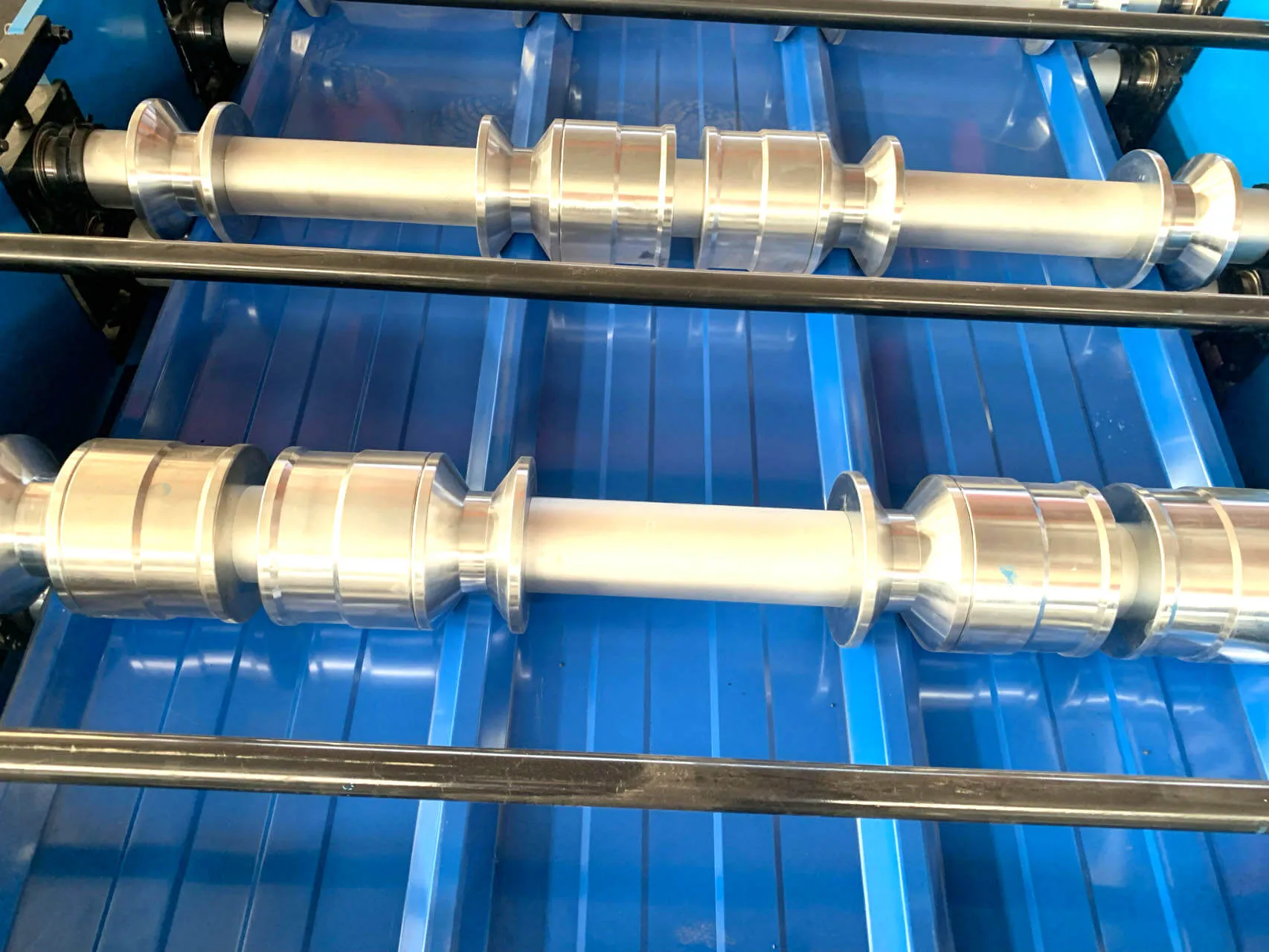

| 4 | diámetro del eje | 70mm, eje sólido | |||||||

| 5 | Material del rodillo | Acero 45#,Superficie cromada espesor 0,05mm ( materiales de acero inoxidable utilizan Cr12) | |||||||

| 6 | Estación de rodillos | 12-22 estaciones (según la forma, el material y la anchura) | |||||||

| 7 | Material de las hojas de afeitar | material:Cr12MOV Procesamiento: rectificado de precisión, corte, tratamiento térmico. Vida útil: 500.000 veces |

|||||||

| 8 | Tipo de cortador | Sistema hidráulico | |||||||

| 9 | Placa intermedia | 16 mm | |||||||

| 10 | Material del bastidor principal | 350H | |||||||

| 11 | PLC | Marca Plc:Delta Idioma: Inglés / Chino |

|||||||

| 12 | caja de control | Armario de control dividido en voladizo | |||||||

| 13 | Rodamiento | Marca china Harbin | |||||||

| 14 | alimentación principal | 5,5 kW + reductor K7 | |||||||

| 15 | potencia de bombeo | 4kw | |||||||

| 16 | Transmisión | Por cadena de 2,5 cm | |||||||

| 17 | codificador | Omron | |||||||

| 18 | Sistema de frecuencias | Dalta(marca taiwanesa) | |||||||

| 19 | sistema táctil | Dalta(marca taiwanesa) | |||||||

| 20 | Tensión | 220V/380V/440V,50/60Hz,3phase | |||||||

Características de la máquina para fabricar láminas metálicas de acero para techos:

|

|

|

Cuchilla de corte de la máquina perfiladoraLa cuchilla de corte es controlada por el sistema de control para establecer un parámetro de longitud fija para el corte, a fin de obtener la longitud deseada. La cuchilla está fabricada con materiales de alta calidad, tiene una larga vida útil, es muy duradera, afilada y de rápida velocidad de corte.

|

Mesa de alimentación de la máquina formadora de rollosLas materias primas se transportan a la perfiladora a través de la mesa de alimentación para su prensado, con el fin de obtener la forma deseada. Esta parte está equipada con un dispositivo de nivelación para facilitar que las materias primas entren en la máquina de forma plana, haciendo que el producto esté mejor formado.

|

Estación hidráulicaEstá controlada por una bomba de aceite de rueda dentada. Después de llenar el aceite hidráulico en el tanque de aceite hidráulico, las bombas impulsan la máquina de corte para comenzar el trabajo de corte. El sistema incluye un conjunto de tanque hidráulico, un conjunto de bomba de aceite hidráulico, dos tuberías hidráulicas. Y un juego de válvulas electromagnéticas.

|

1. 1. Quiénes somos

Somos una empresa de fabricación con sede en Cangzhou, provincia de Hebei, China, fundada en 2013. Nuestros principales mercados de exportación incluyen Sudamérica (30%), Oceanía (20%), África (20%), Norteamérica (10%), Oriente Medio (10%) y el Sudeste Asiático (10%). Nuestro equipo está formado por 11-50 profesionales dedicados a ofrecer excelencia.

2. 2. Garantía de calidad

Pruebas de prototipos antes de la producción a granel

Rigurosos controles finales de calidad antes de la expedición

3. Nuestra gama de productos

Somos especialistas en fabricación:

- Sistemas de perfilado de tejados y paredes

- Maquinaria para la fabricación de tarimas

- Equipos de producción de quillas de acero ligero

- Unidades de perfilado de correas CZ

- Aplanadoras y cortadoras de precisión

4.Ventajas competitivas

① Fabricante de amplio espectro de maquinaria para tejados y equipos relacionados.

② Décadas de experiencia en el sector con soluciones tecnológicas de vanguardia.

③ División de I+D especializada y equipo de atención al cliente 24 horas al día, 7 días a la semana.

5. Capacidades de servicio

- Condiciones de entrega: FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Entrega urgente, DAF, DES

- Divisas de transacción: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF

- Opciones de pago: T/T, L/C, MoneyGram, Tarjeta de crédito, PayPal, Western Union, Efectivo, Escrow

- Idiomas: Inglés, chino, español, japonés, alemán, francés y ruso.