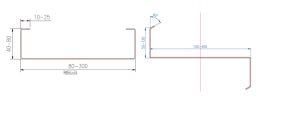

CZ purlin making machine: C80/Z120-300 PLC change size Servomotor drive

|

Steel Purlin Roll Forming Equipment |

||

| 1.In-put material | Guiding shaft and guiding rollers | |

| 2. Flatten | Up three down four additional two stations guiding and sending ,at the same time full solid shaft heat treatment with blasting and chroming. | |

| 3. Forming | 18 stations of main forming (inside 1 station for forming flange, meanwhile 87-95 degree adjustable), then 13 stations CZ change mould, turnover 180 degree to finish the change. Changing the Specification size on Touchscreen.ad | |

| 4. Rib forming | diagonal rib roller 2 sets | |

| 5. Straighten | 10 rollers CZ special-use double axis straightening and 4 rollers double axis straightening, total 2 straightening units. | |

| 6. Guiding and sending | driven by up and down gears | |

| 7. Punch | punch single hole (D14, D16) on web and dual hole (26×16, 26×14) on web , dual hole (26×16, 26×14) on flange | |

| 8. Formed-cut | step-less cutting system, meantime no need change blade, universal size 80-300 blade. | |

Flow direction: Decoiler – Leveling device — pre- punching and pre-cutting – roll forming parts – stack

Technical Highlights:

✔️ Smart Control: Real-time production data monitoring via touchscreen

✔️ Efficient Mold Change: 180-degree rotary mold system (C/Z switching in 3 minutes)

✔️ Durable Design: 40Cr steel quenched main shaft (HRC28-32 hardness)

✔️ Safety Certifications: CE Mark + ISO 9001 Quality Management System

Applicable Industries:

Steel Structure Buildings | Industrial Plants | Logistics Warehouses | Airport & Railway