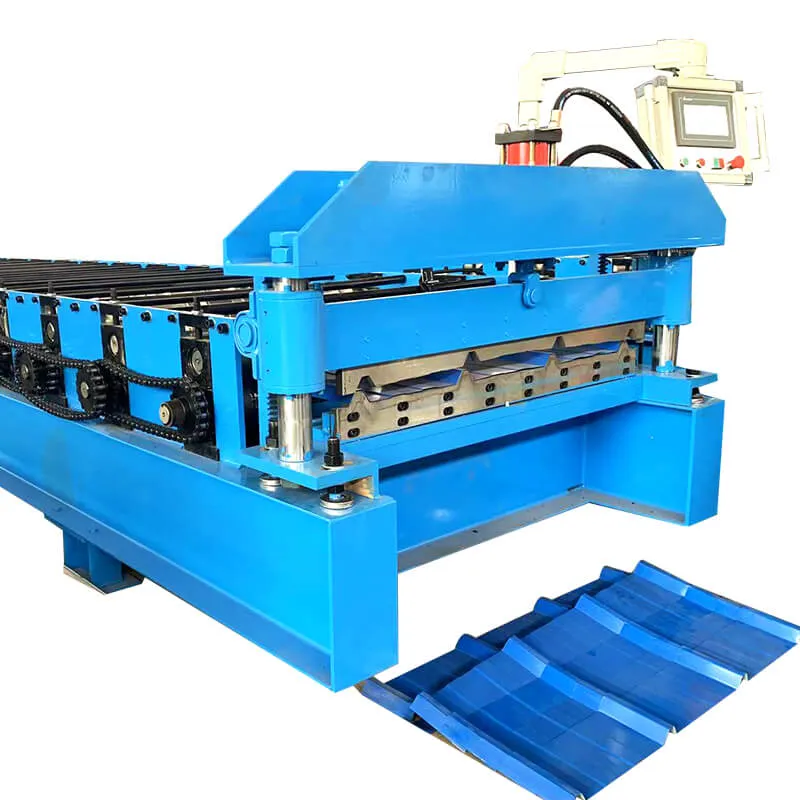

Produce line of components for trapezoildal sheet roll forming machine

Main components of trapezoidal sheet roll forming machine |

|||||||||

| item | Description of Item | Unit | qty | ||||||

| 1 | 5 tons uncoiler | set | 1 | ||||||

| 1 | Feeding & guiding device | set | 1 | ||||||

| 3 | Main roll forming machine | set | 1 | ||||||

| 4 | Hydraulic station | set | 1 | ||||||

| 5 | Controlling system | set | 1 | ||||||

| 6 | Cutting device | set | 1 | ||||||

Main specification of the trapezoidal sheet roll forming machine |

|||||||||

| 1 | materials | PPGL | |||||||

| 2 | materials thickness | 0.3-0.8mm | |||||||

| 3 | Speed | 20-25m/min | |||||||

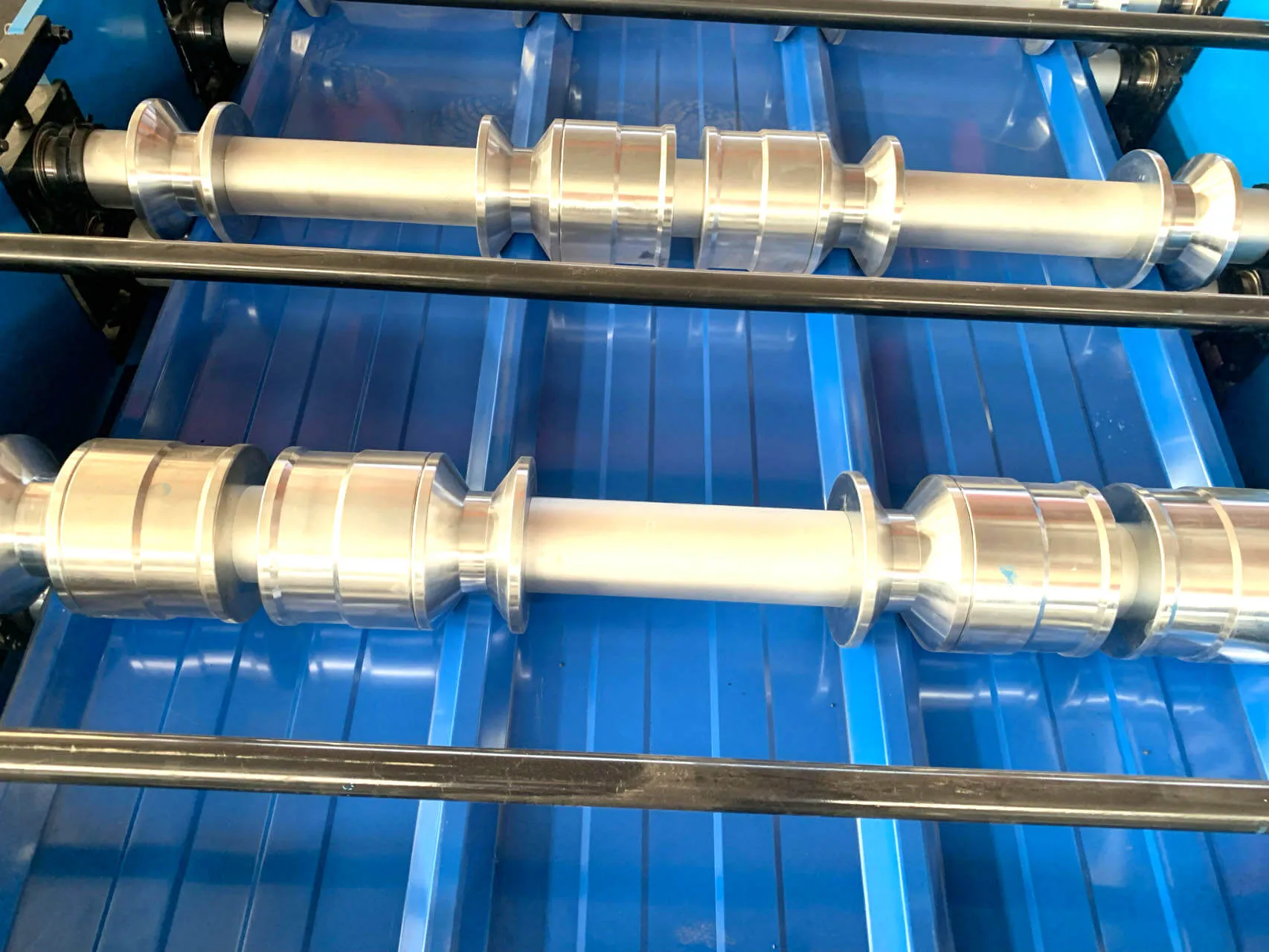

| 4 | shaft diameter | 70mm,solid shaft | |||||||

| 5 | Roller Material | 45# steel,Surface chromed thickness 0.05mm ( stainless steel materials use Cr12) | |||||||

| 6 | Roller station | 12-22 Stations(that according to the different shape,materials,width ) | |||||||

| 7 | Material of razor blades | material:Cr12MOV Processing :precision grinding, cutting, heat treatment. Service life: 500000 times |

|||||||

| 8 | Cutter type | Hydrulic system | |||||||

| 9 | Middle plate | 16mm | |||||||

| 10 | Material of main frame | 350H | |||||||

| 11 | PLC | Plc brand:Delta Language: English / Chinese |

|||||||

| 12 | control box | Cantilever split control cabinet | |||||||

| 13 | Bearing | Chinese famous brand Harbin | |||||||

| 14 | main power | 5.5kw+K7 reducer | |||||||

| 15 | pump power | 4kw | |||||||

| 16 | Transmission | By 1 inch chain | |||||||

| 17 | encoder | Omron | |||||||

| 18 | Frequency system | Dalta(taiwan brand) | |||||||

| 19 | touch system | Dalta(taiwan brand) | |||||||

| 20 | Voltage | 220V/380V/440V,50/60Hz,3phase | |||||||

Feature of Metal Steel Roofing Sheet Making Machine:

|

|

|

Cutting Blade Of Roll Forming MachineThe cutting blade is controlled by the control system to set a fixed length parameter for cutting, so as to obtain the desired length. The blade is made of high-quality materials, has a long life, is very durable, sharp, and fast cutting speed.

|

Feed Table Of Roll Forming MachineRaw materials are conveyed to the roll forming machine through the feeding table for pressing, so as to obtain the shape we want. This part is equipped with a leveling device to facilitate the raw materials to enter the machine in a flat form, making the product better formed.

|

Hydraulic stationIt is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pumps drive the cutter machine to begin the cutting job. The system includes a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And one sets of electromagnetism valves.

|

1. About Us

We are a manufacturing enterprise based in Cangzhou, Hebei Province, China, established in 2013. Our primary export markets include South America (30%), Oceania (20%), Africa (20%), North America (10%), the Middle East (10%), and Southeast Asia (10%). Our team comprises 11-50 professionals dedicated to delivering excellence.

2. Quality Assurance

Prototype testing prior to bulk production

Rigorous final quality checks before dispatch

3.Our Product Range

We specialize in manufacturing:

– Roof & Wall Roll Forming Systems

– Floor Deck Fabrication Machinery

– Light Steel Keel Production Equipment

– CZ Purlin Roll Forming Units

– Precision Leveling & Slitting Machines

4.Competitive Advantages

① Full-spectrum manufacturer of roofing machinery and related equipment.

② Decade-long industry expertise with cutting-edge technological solutions.

③ Dedicated R&D division and 24/7 customer support team.

5. Service Capabilities

– Delivery Terms: FOB, CFR, CIF, EXW, FAS, CIP, FCA, CPT, DEQ, DDP, DDU, Express Delivery, DAF, DES

– Transaction Currencies: USD, EUR, JPY, CAD, AUD, HKD, GBP, CNY, CHF

– Payment Options: T/T, L/C, MoneyGram, Credit Card, PayPal, Western Union, Cash, Escrow

– Languages: English, Chinese, Spanish, Japanese, German, French, Russian